Main Lines

Two-cut process

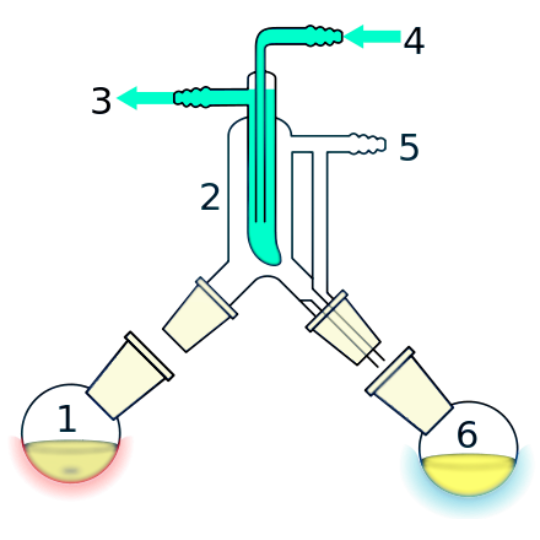

This is a two-cut process, where the terpenes and cannabinoids are distilled in the first and second cuts respectively.

Optimization

In this experiment, the effects of distillation parameters in the second cut and the internal condensation temperature (60-90°C), were examined and optimized using a rotating central composite plane to maximize cannabinoid mass and recovery efficiency in the distillate and minimize cannabinoid mass in the residue.

Yield

Under these optimized conditions, the recovery yield of tetrahydrocannabinol in the distillate was 93.4%.

Conclusion

This study provides distillation conditions to be taken into account by the cannabis industry if it wishes to obtain a cannabinoid-rich distillate from the molecular distillation process without affecting cannabinoid quality.

Few studies have explored molecular distillation techniques that can improve cannabinoid recovery from crude cannabis oil with scale-up potential.

Short-path molecular distillation on wiped film is commonly used in the cannabis industry to separate cannabinoids from terpenes and heavy compounds.

Our research into the optimization of molecular distillation parameters for the production of cannabis-based products is important for the following reasons:

- The researchers found that adjusting the distillation rate and temperature can maximize the amount of cannabinoids recovered in the final product while minimizing the amount of cannabinoids remaining in the residue.

- This research is relevant to the legal cannabis industry because it can improve the efficiency of cannabis product production, by increasing the concentration of cannabinoids in finished products while reducing waste.

- Ultimately, this may lead to higher-quality, more profitable products for legal cannabis producers.